Edge Management: The Protection of Ropes

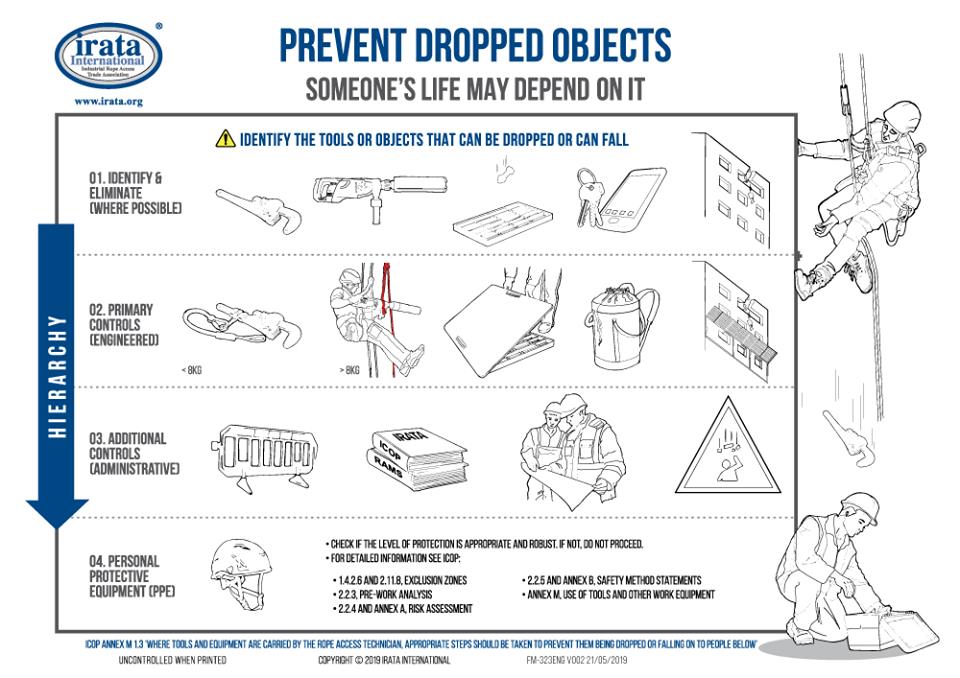

In rope access work it is vital to ensure that ropes are protected with a suitable method. A hierarchical approach should be adopted in order to determine the best achievable method of protection for ropes at a worksite.

“It is essential that precautions are taken to prevent damage to anchor lines, when they are in use. …”

ICOP, 2.11.3.2.1

Once it has been established that rope access is an appropriate access system, and the hazards have been identified, the following process should be followed:

- Remove (the hazard, where feasible)

- Avoid (the hazard)

- Protect (against the hazard).

This process may be remembered by the acronym ‘RAP’. This hierarchy is listed in a decreasing order of priority. Accordingly, the most effective and reliable edge management measures will be those at the top of the hierarchy.

1. IDENTIFY 2. REMOVE 3. AVOID 4. PROTECT 5. VERIFY

“Great care should be taken when choosing an anchor line protector that it is going to offer sufficient protection against the surface with which it may be in contact. It should be able to withstand use in the chosen location without wearing through or melting and exposing an anchor line to the abrasive or hot surface. Anchor line protectors used to protect against hot surfaces should be of a type intended for this purpose” – ICOP, 2.11.3.2.7

You can read more about the protection of ropes in the recently published IRATA Topic Sheet.